Iron and Steel Roll factory introduction

Our factory annual capacity is up to 100,000 tons rolls. It is equipped with the advanced production, inspection and test equipments, including 8 medium frequency furnaces of 20t/30t duplicate supply revert medium-frequency furnace and 10t, 5t and 3t medium-frequency furnaces made by Inductotherm Group USA.30t arc furnace,1 respectively 60t LF refined-smelting ladle furnace, 60t VD vacuum refining furnace and V.C. vacuum pouring furnace, 3 centrifugal casting machines, 18 high and low temperature resistance furnaces and 3 open-type differential temperature quenching furnaces. Heavy-duty NC lathe, NC grinding machine, NC milling machine, NC boring lathe, as well as the Ultrasonic flaw detector, front-view metallurgical phase microscope, metallographic image analyzer, carbon-sulfur analyzer, hydrogen, oxygen and nitrogen analyzer, metallurgical phase hardometer, dilatometer, scanning electron microscope, thermal analyzer, direct-reading spectrometer, Brinell hardness meter, Rockwell apparatus, profile sand tester, profile sand hardness gauge, profile sand coating thickness gauge, tension test machine, impact test machine and etc.

Factory Iron and steel rolls production schedule introduce:

1. Engineer review the sales contracts and make the production technology process, arrange the production time.

2. Smelt iron and analyse the chemical composition by spectral detector ; Inspect the liquid iron temperture and control the melting time.

We use China best quality pig iron as main raw materials, not use scrap steel materials.

We have high-quality molten steel (iron) smelting equipment such as electric-arc furnace, ladle refining furnace, power frequency furnace and intermediate frequency furnace.

Use Germany brand : SPECTROLAB spectral detector to make sure iron liquid of correct chemical position.

3. Casting the rolls

We can do both static cast and centrifugal cast way, depends on the rolls type and size.

15pcs centrifugal cast machine.

4. Rolls for rough machining

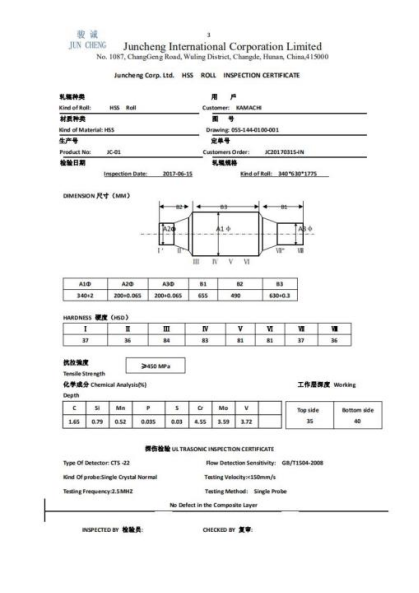

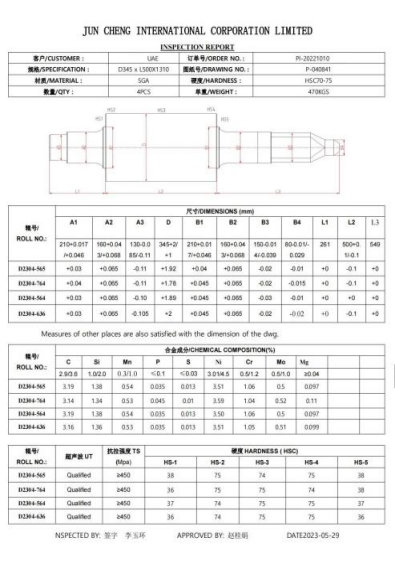

After rough machining, we inspect the hardness, tensile strength, ultrasonic flaw detection.

5. Heat treatment

we have 20 sets heat treatment furnace.

After heat treatment, we inspect the metallographic structure and hardness.

6.Finish machining

Turning the oxide layer, and grinding to the need tolerance.

We have more than 80 sets CNC machine for processing rolls.

We meet the roll drawings requirements by inspection all size and details, do the ultrasonic test and issue the inspection report to client.