Mill Roll Processing Machinery

-

Tungsten Carbide Roll CNC Grinding Machine

This machine uses a diamond wheel as cutting tool, and it is mainly designed for rough, semi-fine, fine and spark-out grinding of the cylindrical surface of tungsten carbide roll and its arc-shaped slots, applied in high-speed wire production industry, with high accuracy and strong power.

Send Email Details -

Mill Roll CNC Notching Machine

The CNC Notching and Marking machine mode JCK-500C is specially designed for notching and marking on the cast iron, high speed steel and tungsten carbide rolls. This multifunctional machine has obtained Chinese national patent It applies SIEMENS controlled system with high efficiency and precision.

Send Email Details

Four main shafts are controlled by independent servo motors and drives. Currently, JCK - 500C CNC notching and marking machine is the most popular model in Chinese and World* s market for this application.

The Model JCK-500K is the latest multifunctional notching and marking machine with highest automation and fastest processing speed. It adopts SIEMENS 828D controlled system, SIEMENS servo motors and full color LCD display. Five main shafts are controlled by independent servo motors and drives. Since JCK-500K needs not manual operation during machining process, it is the upgraded version of JCK-500C notching and marking machine with higher level of efficiency and precision. JCK-500K is the best solution for your business. -

Normal Diamond Wheel Repairing Machine

This machine uses a green carbon silicon wheel as cutting tool, mainly to dress the arc-shaped slot and the cylindrical surface of the diamond wheel.

Send Email Details -

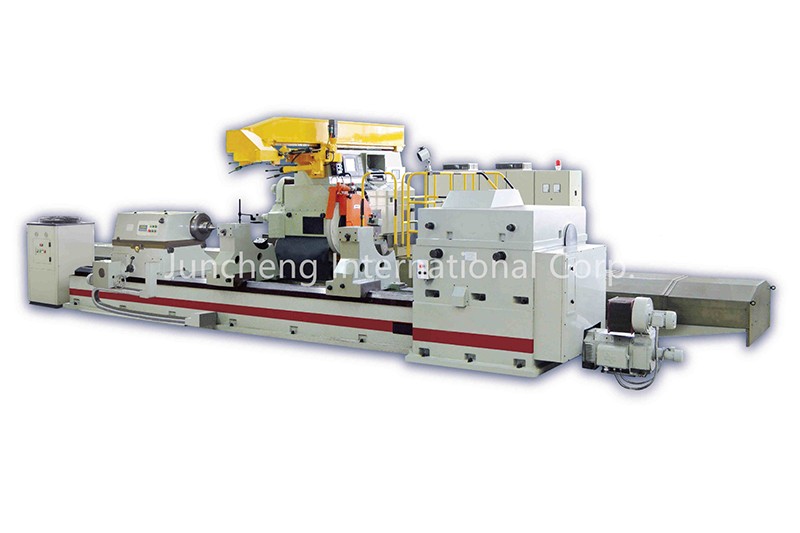

Large Mill Roll CNC Grinding Machine(max dia. 3m)

The machine is equipped with "CP” automatic measurement system,which can perform in-process and post-process measurements.The system can be used to measure the diameter, roundness, concentricity, cylindricity and profile etc.of the workpiece.All of the measurement results can be observed in the screen and printed.

Send Email Details

All of the measurements are performed with two measuring arms before & after the grinding. And all of the measurements can be combined with the grinding program to perform automatical operation. To avoid the false operation, all of the movements and measurements of the measuring head should be carried out automatically, not be disturbed by the operater.

All the optical scales are HEIDNAIN from Germany,and its accuracy is 1-5 um, 0.5-1 um. -

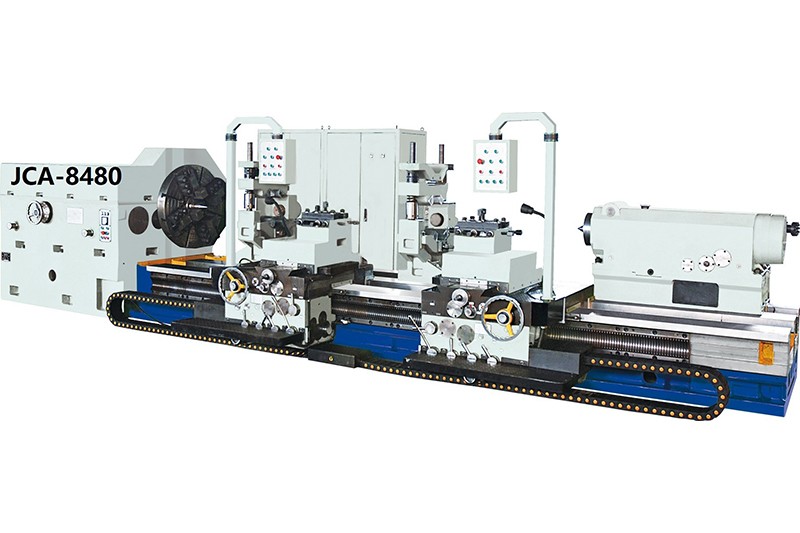

Mill Roll CNC Turning Lathe

The series of machine tools are CNC roll machine tools, mainly used for semi-finish turning and finish timing processing of cast Iron, steel and nonferraus metal roll. Cutters made of high-speed steel, cemented carbide or other materials can be used for turning and repair processing of roll excircle end faces, various complex pass profiles and curved surface, or for the processing of shaft parts ( which have the same dimension and weight as above mentbned rolls ) made of materials such as cast iron, steel and nonferrous metal, or the semi-finish turning and finish turning of excircle, end faces and various complex curved surfaces.

Send Email Details -

Diamond Wheel Electric Spark Repairing Machine

Adopting the electric discharge principle for machining, the equipment uses graphite wheel as the tool electrode to perform electric discharge machining on the outer diameter of metal bonded diamond grinding wheel. It is specially applied for producing and dressing diamond grinding wheel in grinding wheel and steel industries. It has the advantages of no limitation by the hardness of produced material and capability of machining different types of grinding wheels with different outer diameter contours. And it is an ideal domestic equipment for machining and dressing the grinding wheel.

diamond wheel electric spark repairing machine Spark Repairing Machine diamond wheel processing machineSend Email Details -

Mill Roll Digital Display Turning Lathe

This series of machine tools are especially designed and employed for processing the barrels and passes of rolls in steel mills. It uses forming tools to process and repair the passes of various rolls, to conduct rough machining on the outer cylindrical surfaces of rolls as well as to process other shaft parts.

Send Email Details -

Tungsten Carbide Roll Digital Display Grinding Machine

This machine uses a diamond wheel as cutting tool, and it is mainly designed for rough, semi-fine, fine and spark-out grinding of the cylindrical surface of tungsten carbide roll and its arc-shaped slots, applied in high-speed wire production industry, with high accuracy and strong power.

Send Email Details -

Composite And HSS Roll CNC Grinding Machine

This machine is mainly used for rough grinding, semi-precision grinding, fine grinding and non-sparking of the outer circle and R-groove of tungsen carbide composite roll or high-speed steel roll for bar or coil production. Grinding and other grinding processes, at the same time, after the installation of the transition disk, the automatic centering and tightening mandrel can be used to process a single roll ring, which expands the use of the machine tool.

Send Email Details