- Juncheng

- China

- 60 days to 120 days

- 30sets/month

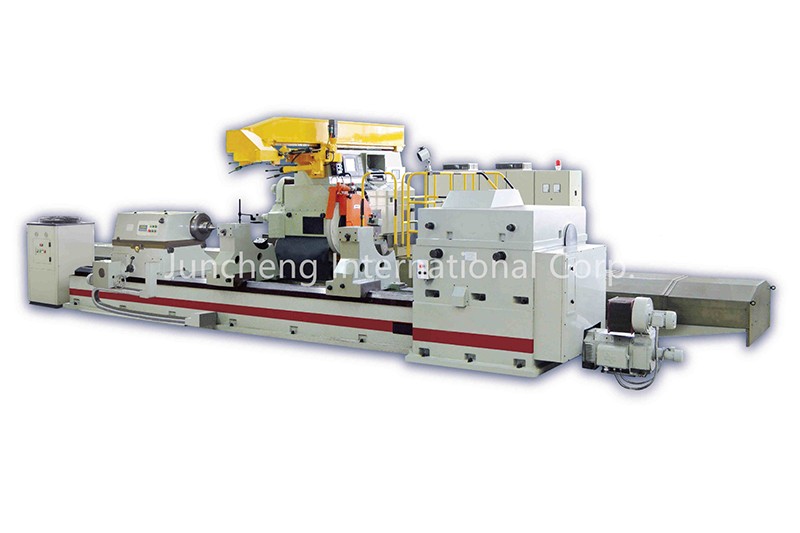

This machine is mainly used for rough grinding, semi-precision grinding, fine grinding and non-sparking of the outer circle and R-groove of tungsen carbide composite roll or high-speed steel roll for bar or coil production. Grinding and other grinding processes, at the same time, after the installation of the transition disk, the automatic centering and tightening mandrel can be used to process a single roll ring, which expands the use of the machine tool.

Composite Roll and HSS Roll CNC Grinding Machine

Working range:

| Roll ring diameter ground: | φ220~φ500mm |

| Max. roll ring length: | 2000mm |

Working accuracy:

| Outside cylindricity deviation: | ≤0.015mm |

| Outside diameter tolerance: | ±0.005mm |

| Roll ring root diameter tolerance: | ±0.01mm |

| Roll slot depth tolerance: | ±0.005mm |

| Ground surface roughness tolerance: | Ra≤0.8μm |

| Ground surface coaxiality with regard to centering bore: | ≤0.005mm |

| Grinding wheel frame repeated positioning accuracy : | ≤0.005mm |

| Position tolerance of center line of roll slot with regard to the end-face of roll ring: | ±0.01mm |

Strength of the machine:

1) The machine bed adopts integral casting structure, and after aging treatment, it has good structural rigidity and accuracy retention.

2) The machine tool adopts the German SIEMENS 828D numerical control system, which automatically controls the horizontal feed of the grinding wheel and the reciprocating movement of the worktable. The positions of the grinding wheel frame and the worktable are dynamically displayed on the CRT, and the outer surface of the roller surface and the tool setting are automatically completed Grinding of grooves.

3) The outer diameter of the diamond grinding wheel used in the machine tool is φ200-φ250mm, and the maximum thickness is 65mm. The connection parameters of the main shaft extension end of the wheel carrier must be completely consistent with the corresponding connection parameters of the separately signed "JCW-014A / 1 diamond wheel dresser" to ensure the dress The diamond wheel can be used correctly.

4) The spindle system of the grinding wheel frame adopts German FAG rolling bearing support or dynamic and static pressure bearings. The system has the characteristics of high rigidity, high precision, and strong grinding force, especially for improving the smoothness of workpiece grinding. Greatly reduce the cost of using machine tools and create more benefits.

5) The speed of the headstock can be adjusted steplessly, and the speed range is 20-130 rpm. The main shaft is supported by German FAG rolling bearings (the front bearing adopts double-row cylindrical roller bearings and bidirectional thrust angular contact ball bearings, and the rear bearing adopts angular contact ball bearings), which can bear both radial and axial forces.

6) The power of the motor for driving the spindle of the grinding wheel is 18.5kW, which is driven by the polyurethane multi-ribbed belt, and its rotation speed is 1910r / min.

7) The guide rail of the worktable adopts open-type unloading lubrication, the guide rail surface is plastic-coated, and the friction force is small.

8) The high-precision ball screw is used for the grinding wheel frame and the worktable, which is driven by the servo motor of SIEMENS company. The movement of the grinding wheel frame and the worktable can be automatically controlled by the program to complete the forming grinding of the outer surface of the roller surface and the hole groove, and can also be completed by the electronic hand wheel.

9) The machine tool is equipped with an independent cooling system and a cooling liquid purification device, and the filtering and cooling effects are obvious.