- Juncheng

- China

- 60 days to 120 days

- 50sets/month

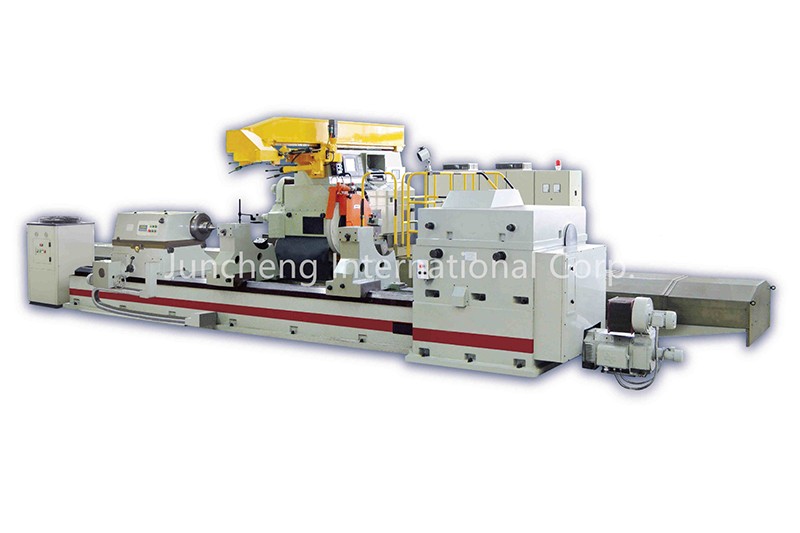

This machine uses a green carbon silicon wheel as cutting tool, mainly to dress the arc-shaped slot and the cylindrical surface of the diamond wheel.

Diamond Wheel Repairing Machine

1. Working range:

Diamond wheel diameter dressed: | φ190~φ250mm |

Max. width of diamond wheel dressed: | 45mm |

Arc-shaped slot of diamond wheel dressed: | R2.5~R34 mm |

2. Working accuracy:

Outside cylindricity deviation: | ≤0.005mm |

Arc-shaped slot contour deviation: | ≤0.01mm |

Ground surface coaxiality with regard to the centering bore: | ≤0.005mm |

3. Structural Features and others:

3.1 The machine-bed is formed of an integral casting, with ageing treatment, and so it has excellent structural rigidity and accuracy retentivity.

3.2 Workpiece (diamond wheel) and the green carbon silicon wheel are respectively driven by their individual motors. Workpiece centering device is operated by hand, and centering inspection is done by optical projector, with the min. feed of handwheel being 0.01mm, both the longitudinal and cross travel not less than 50mm in horizontal plane, moreover, the centering adjustment is provided with locking device.

3.3 The jointing dimensions of the spindle stretching end of the diamond wheel to be dressed must be completely concordant with those of the wheel spindle stretching end of the “Special-Purpose Roll Ring Grinder”.

3.4 The green carbon silicon wheel is 250 mm in diameter, 20mm in width, with its peripheral velocity 35m/s.

3.5 The max. travel of the green carbon silicon wheel is 65mm, with its min. feed amount being 0.01mm, and its feed actuated manually.

3.6 The green carbon silicon wheel arcing movement is performed manually, with its max. arc swinging angle being 1800. Its axial reciprocating swinging is obtained by power-drive, with its swinging speed 30 dual-times per minute, and max. swinging length 20mm.

3.7 Working contour accuracy of the wheel dressing machine should be up to 0.01mm, i.e. the dressed diamond wheel contour permissible error ≤0.01mm.

3.8 The machine shall be equipped with guarding device for the cooling system, and the optical projector supplied with the machine shall make the inspection of the dressed profile, featuring 10-multiple enlarging, with clear projection. The optical projector inspecting accuracy shall be up to 0.01mm.

4. Main accessories supply with machine

SK014A/1 diamond wheel dressing machine | 1 set |

Optical projector supplied with machine | 1 set |

Cooling system and necessary accessories | 1 set |

Green carbon silicon wheel for dressing the diamond wheel | 3 pcs |

Green carbon silicon wheel chuck | 1 set |

Leveling wedge | 4 sets |

Wheel balancing stand and balancing mandrel | 1 set each |

Organic glass arc-shaped slot enlarged template | 3 pcs |

Technical documents supplied with machine | 1 set |

(including the Test Certificate and Operation Manual of the machine, the Test Certificate and Operation Manual of the optical projector, and Packing List etc.) | |

5. On condition that the transport safety is ensured, the machine shall be packed in accordance with the export packing standards, and also conform to the rules concerning transportation and hoist.

Remarks:

The above-mentioned quotation includes the package fee, inspection fee and the cost of all above-mentioned supplies. While the commission and installation fee as well as the training fee will be quoted separately.