- Juncheng

- China

- 30 days to 60 days

- 50sets/month

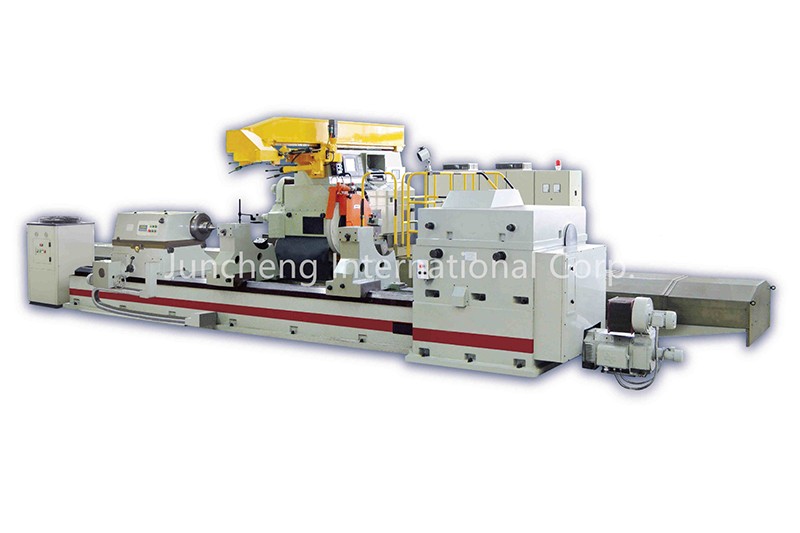

This machine uses a diamond wheel as cutting tool, and it is mainly designed for rough, semi-fine, fine and spark-out grinding of the cylindrical surface of tungsten carbide roll and its arc-shaped slots, applied in high-speed wire production industry, with high accuracy and strong power.

Tungsten Carbide Roll CNC Grinding Machine JCG-400-CNC

Working range:

| Roll ring diameter ground: | φ220~φ500mm |

| Max. roll ring length: | 2000mm |

Working accuracy:

| Outside cylindricity deviation: | ≤0.015mm |

| Outside diameter tolerance: | ±0.005mm |

| Roll ring root diameter tolerance: | ±0.01mm |

| Roll slot depth tolerance: | ±0.005mm |

| Ground surface roughness tolerance: | Ra≤0.8μm |

| Ground surface coaxiality with regard to centering bore: | ≤0.005mm |

| Grinding wheel frame repeated positioning accuracy : | ≤0.005mm |

| Position tolerance of center line of roll slot with regard to the end-face of roll ring: | ±0.01mm |

Strength:

1) Its performance and technical parameters are same or even better than HERKULES.

2) Grinding method: mechanical grinding, which can perform profile grinding and profiling grinding.

3) The power of the grinding wheel motor is 18.5 kilowatts, and the power of the headstock motor is 5.5 kilowatts, so the grinding efficiency is high.

4) The numerical control system adopts the German SIEMENS-828D numerical control system, the longitudinal movement of the worktable and the horizontal feed motion of the grinding wheel frame are driven by two German SIEMENS servo motors, and the minimum pulse equivalent is 0.001mm. Control two servo units and various auxiliary actions of machine tools to realize automatic cycle grinding of machine tools. The motor in the servo system is controlled by the CNC and moves according to the program edited by the numerical control. The console is equipped with a liquid crystal display. The system has automatic diagnosis, fault alarm, and man-machine dialogue functions. It is not the 802C low-grade single-axis industrial control system specially produced by Siemens in China for some domestic grinding machine manufacturers. Therefore, the whole machine has simple operation, reliable performance and good stability. The CNC grinders that have been sold so far have not had electrical failures.

5) After the entire program is set, only one button can be used to complete rapid feed, rough grinding, semi-finish grinding, fine grinding, non-spark grinding, retracting the tool.