- Juncheng

- China

- 30 days to 60 days

- 50sets/month

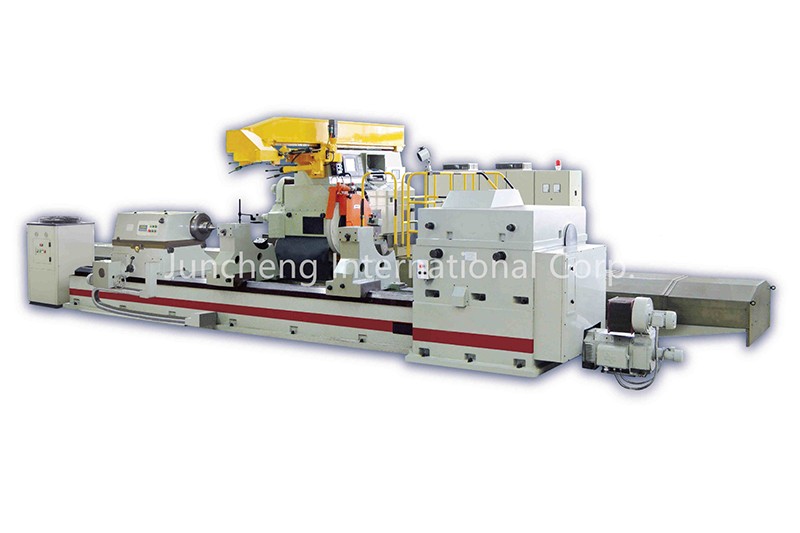

Adopting the electric discharge principle for machining, the equipment uses graphite wheel as the tool electrode to perform electric discharge machining on the outer diameter of metal bonded diamond grinding wheel. It is specially applied for producing and dressing diamond grinding wheel in grinding wheel and steel industries. It has the advantages of no limitation by the hardness of produced material and capability of machining different types of grinding wheels with different outer diameter contours. And it is an ideal domestic equipment for machining and dressing the grinding wheel.

Diamond Wheel Electric Spark Repairing Machine

No. | Name of parameter | Unit | Specification |

1 | Outer diameter of produced workpiece | mm | φ40~φ400 |

2 | Width of produced workpiece | mm | 6~60 |

3 | Outer diameter of graphite wheel | mm | φ200~φ300 |

4 | Height from spindle center to working table surface | mm | 220 |

5 | Distance between two centers | mm | 420 |

6 | Rotation speed of workpiece spindle | r/min | 0~4 |

7 | Rotation speed of graphite wheel | r/min | 16 |

8 | Longitudinal travel of graphite wheel | mm | 180 |

9 | Transverse travel of graphite wheel | mm | 120 |

10 | Motor of workpiece spindle | set | 90BC5100A Voltage: 24V Stepping angle:0.36°/0.72° Holding torque:2.156N·m |

11 | Motor of graphite wheel | Set | YSCJ90-120 120W |

12 | Working liquid pump | Set | CM90/22T 0.37KW 90L/min |

13 | Volume of working liquid tank | L | 200 |

14 | Volume of oil sink | L | 130 |

15 | Gross weight of equipment | T | 3 |

16 | Outline dimensions of equipment | mm | 1260 (length) × 1655 (width) × 1630 (height) |