- Juncheng

- China

- 60 days to 120 days

- 30sets/month

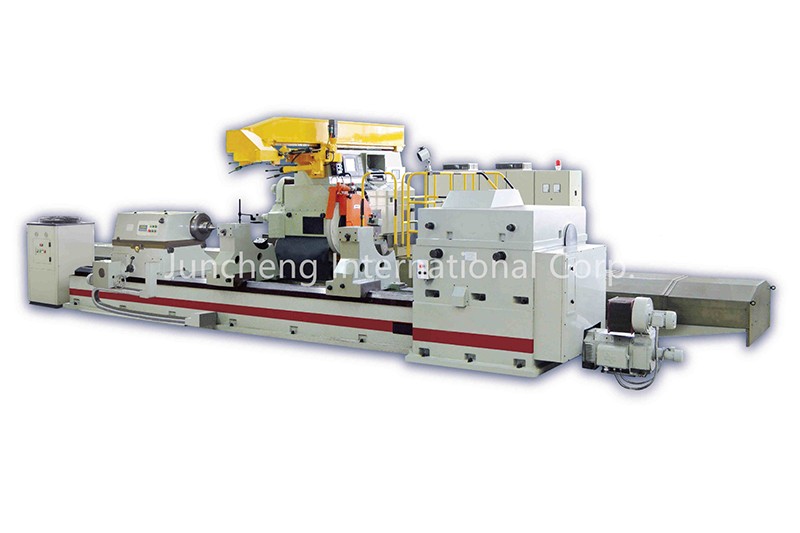

This series of machine tools are especially designed and employed for processing the barrels and passes of rolls in steel mills. It uses forming tools to process and repair the passes of various rolls, to conduct rough machining on the outer cylindrical surfaces of rolls as well as to process other shaft parts.

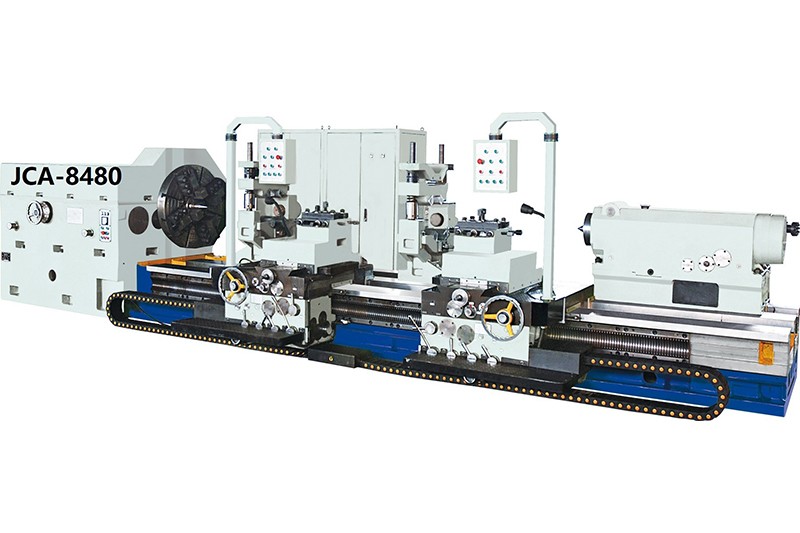

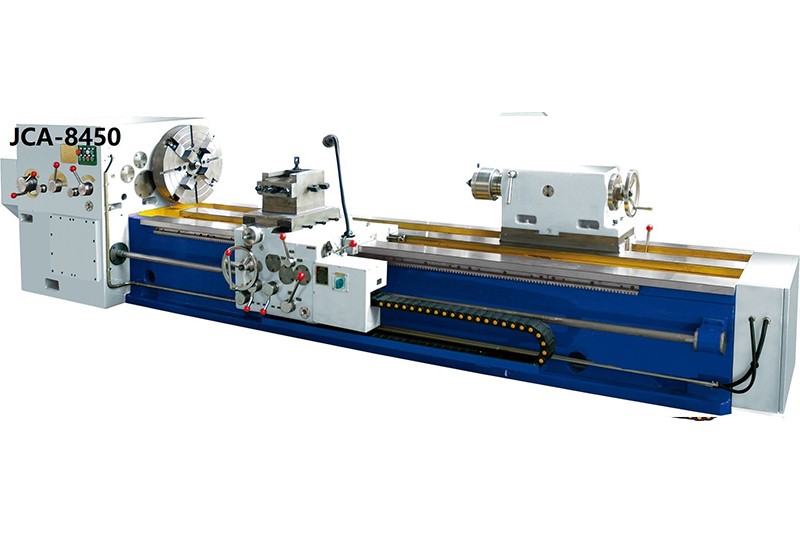

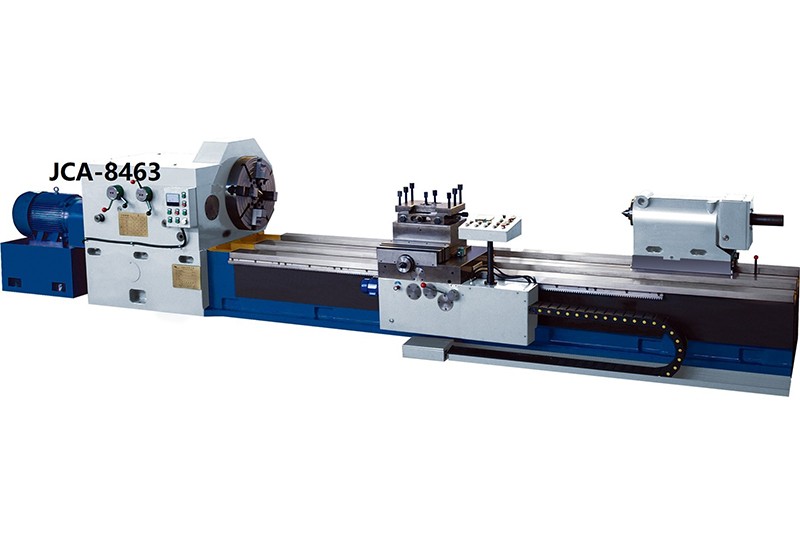

Mill Roll Digital Display Turning Lathe

Main Technical Parameters

Item | Unit | JCA-8450 | JCA-8463 | JCA-8480 | ||

Diameter range of workpiece | mm | 500 | 230-650 | 360-800 | ||

Max.workpiece length | mm | 2500 | 3500 | 4000 | ||

Center height | mm | 320 | 380 | 550 | ||

Max. notching force of single tool carrier | KN | 40 | 60 | 70 | ||

Max. torque of faceplate | KN.m | 10 | 25 | 55 | ||

Number of steps & range of spindle speeds | r/min | 16 | 1-112 | 16 1-75 | 16 | 1-31.5 |

Number of steps & range of tool carrier to feed | mm/min | 12 | Longitudinal: | PLC Control 16 steps | 12 | Longitudinal: |

0.18-8 | 0.4-18 | |||||

Transversal: | Transversal: | |||||

0.045-2 | 0.2-9 | |||||

Travel of tailstock sleeve | mm | 150 | 200 | 300 | ||

Diameter range of centre rest to clamp | mm | 165-250 | 200-300 | 300-400 | ||

Power of main motor | KW | 15 | 22 | 37 | ||

Overall dimensions of the machine (L x Wx H) | mm | 5155x1368x1400 | 7042x1571x1520 | 9240x2280x1800 | ||

weight of the machine | kgs | 7500 | 14000 | 28000 | ||