- Jun Cheng

- China

- 100 days to 150 days

- 80000tons/year

Roll performance: The outer layer composition has lower carbon content and higher chromium alloy content. After the roller is quenched and tempered multiple times, the outer layer structure is tempered bainite + carbide, and the strength and impact toughness are significantly improved. , the core is made of high-strength ductile iron, and its overall performance is significantly better than other cast steel support rollers.

Centrifugal cast Cr4 alloy steel roll

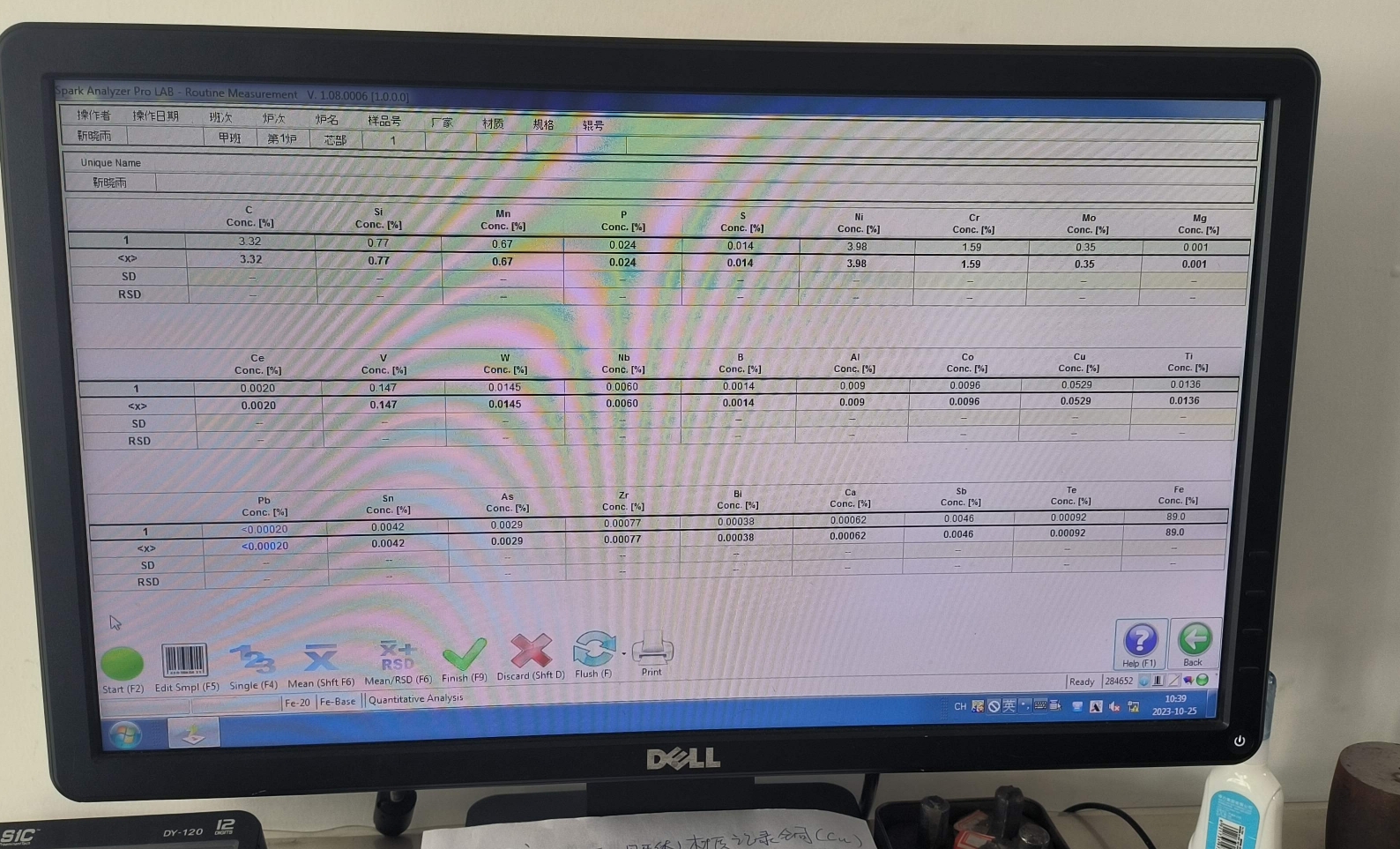

Chemical

Grade | C | Si | Mn | Ni | Cr | Mo | V |

Cr4 alloy steel | 0.4/0.6 | 0.4/0.7 | 0.5/1.0 | 0.3/0.8 | 3.0/5.0 | 0.3/0.8 | 0.1/1.0 |

Mechanical

Hardness | Centrifugal |

|

Shell | HSD55-70 | |

Core | HSD35-45 | |

Core TRS | >=500 Mpa | Mag X 100 |

Application:

Hot rolling steel sheet and coil back-up roll.