- Jun Cheng

- China

- 100 days to 150days

- 80000tons/year

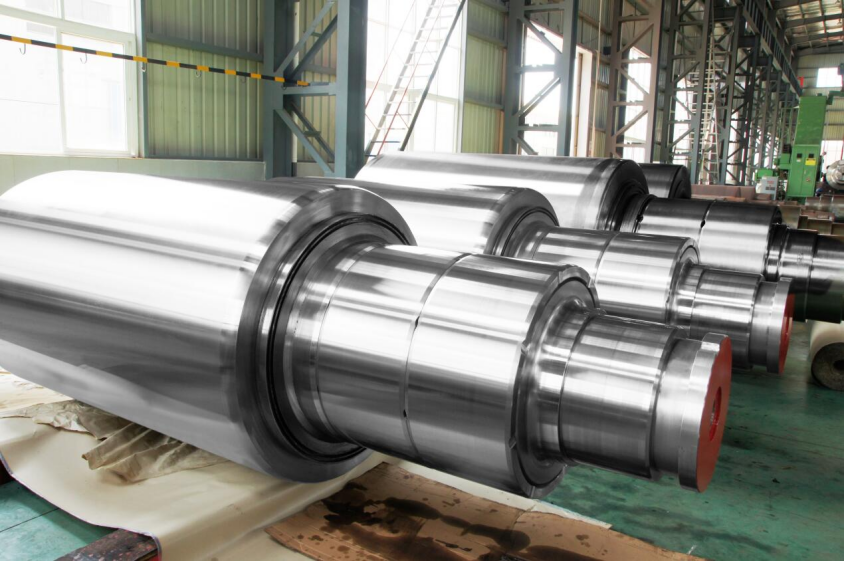

Main dimention of rolls ,Max dia. of roll : 1400mm Max length of roll :6000mm

Worklayer hardness :60- 100HSC Neck hardness : 40 - 88HSC

Worklayer thickness: 25 - 140mm

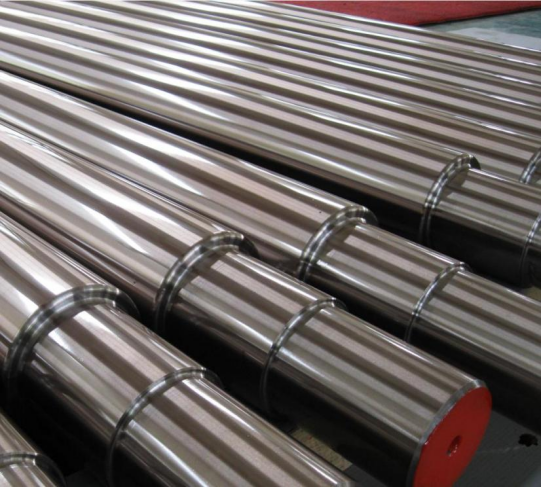

Our forged steel rolls barrel hardness is good , it can be controled within HSD0.2 , and min

single worklayer is up to 25mm.

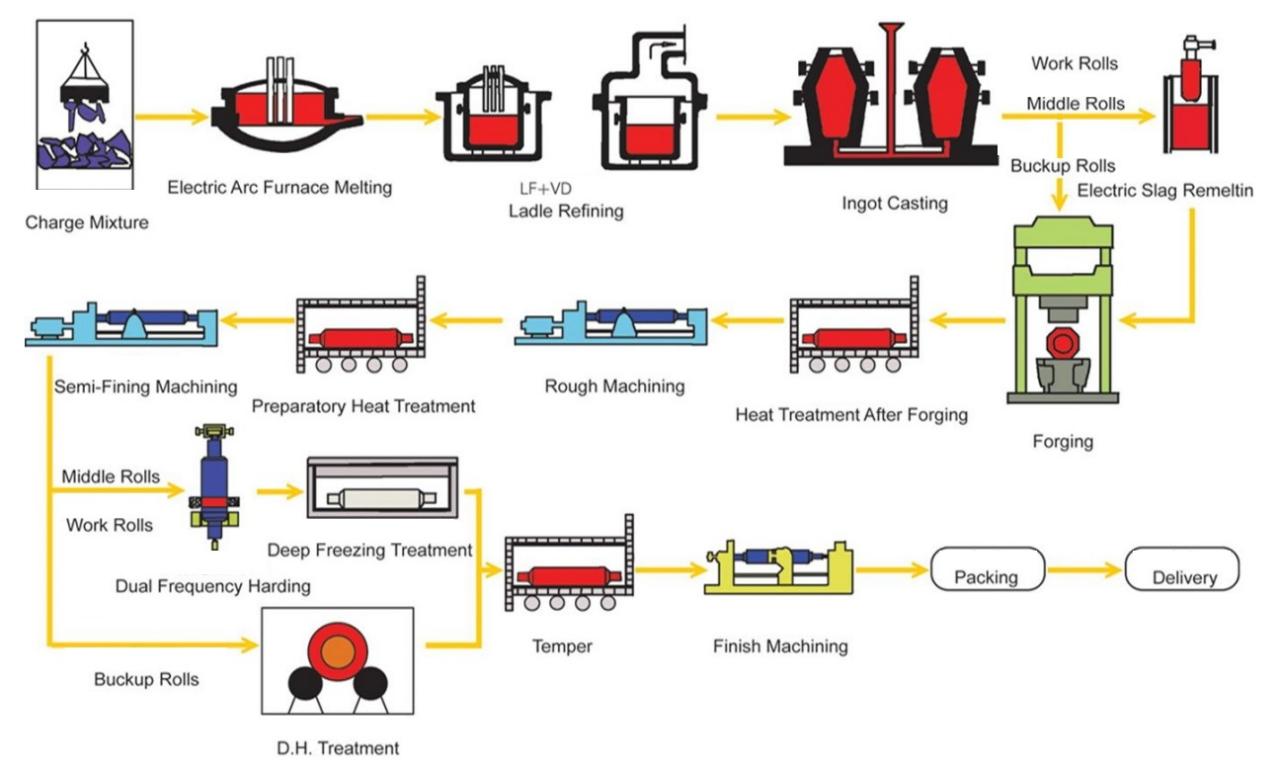

Forged steel roll main production procedures :

Forged Steel Work Roll

Forged Steel Intermediate Roll

Forged Steel Back-up-Roll

Forged Steel Sendzimir and Cluster Mill Roll

Grade |

C |

Si |

Mn |

Cr |

Ni |

Mo |

V |

P |

S |

Cr3 | 0.82-0.9 | 0.6-0.9 | 0.2-0.45 | 2.8-3.2 | 0.6-0.8 | 0.4-0.6 | 0.05-0.15 | =<0.015 | =<0.02 |

Cr5 | 0.8-0.9 | 0.3-0.55 | 0.2-0.5 | 4.8-5.4 | 0.3-0.5 | 0.2-0.4 | 0.05-0.12 | =<0.015 | =<0.02 |

50-70CrNiMo | 0.6-0.75 | 0.4-0.7 | 0.5-0.9 | 2.0-3.5 | =<0.6 | 0.25-0.6 | ------ | =<0.03 | =<0.03 |

45Cr5NiMoV | 0.48-0.55 | 0.3-0.55 | 0.2-0.5 | 4.9-5.4 | 0.3-0.5 | 0.3-0.5 | 0.1-0.2 | =<0.015 | =<0.02 |

Grade | Application | Depth of hardness -mm |

Cr3 | Work roll and intermediate roll | 25 |

Cr5 | Work roll and intermediate roll | 35 |

50-70CrNiMo | Hot work roll and back-up roll | 50 |

45Cr5NiMoV | Back-up roll | 75 |

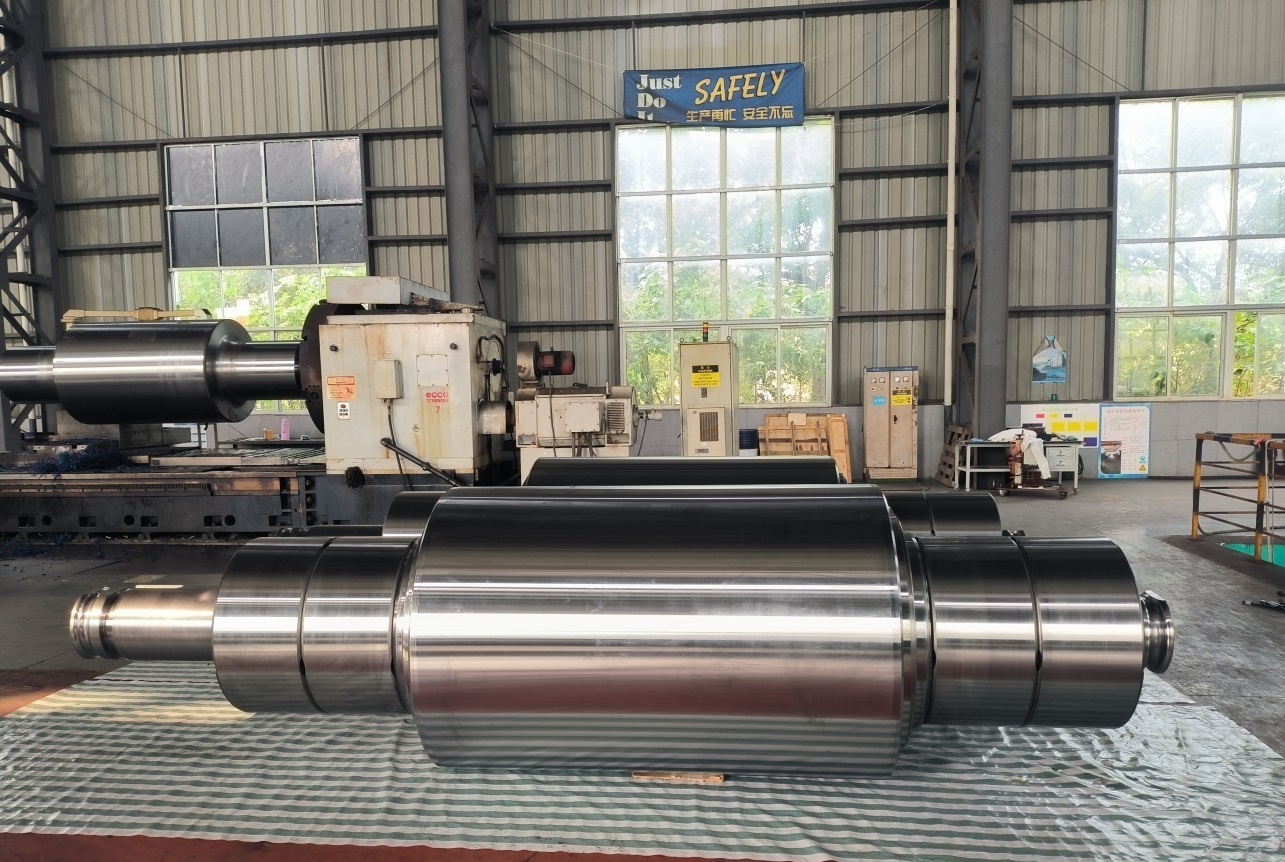

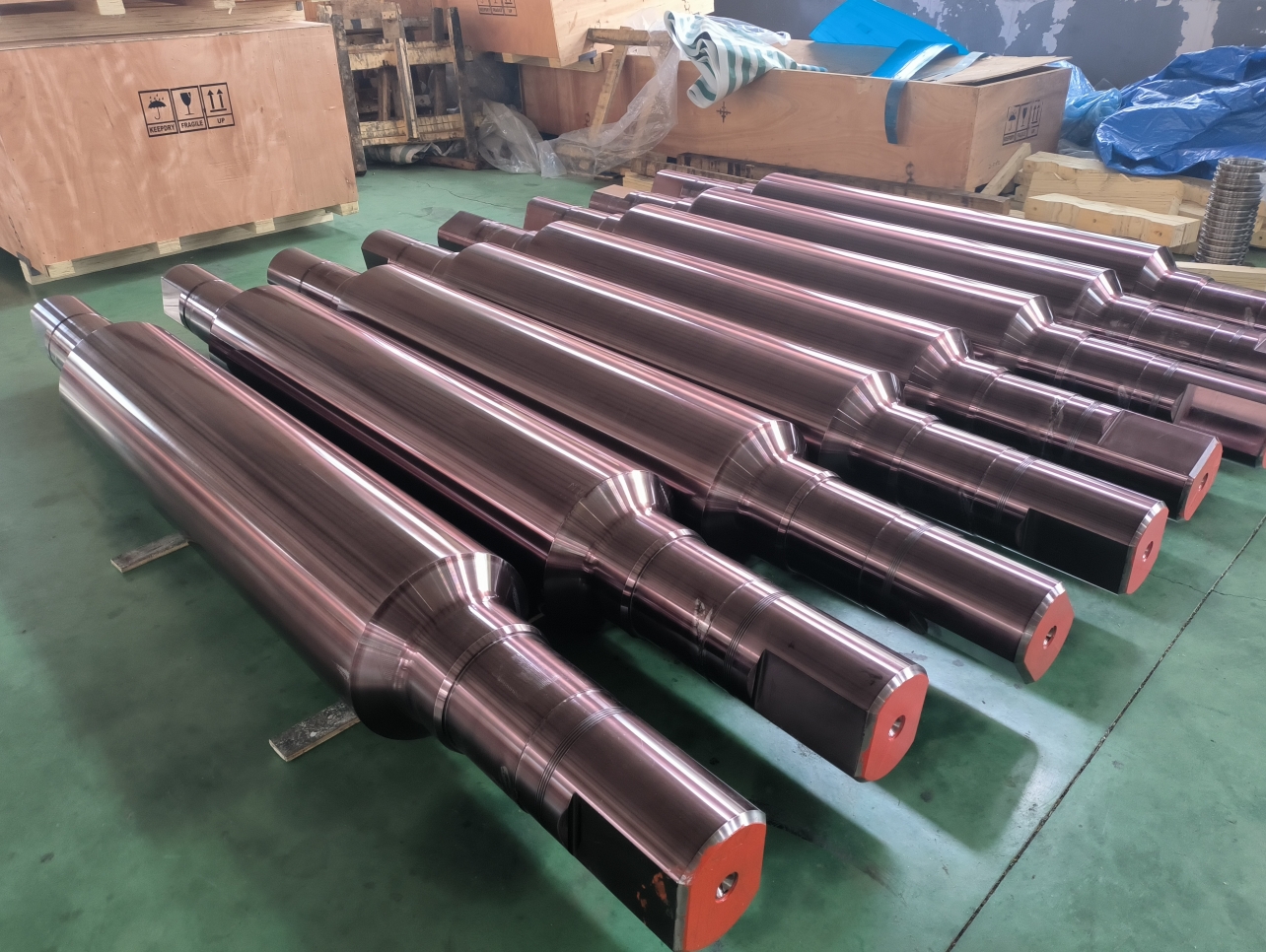

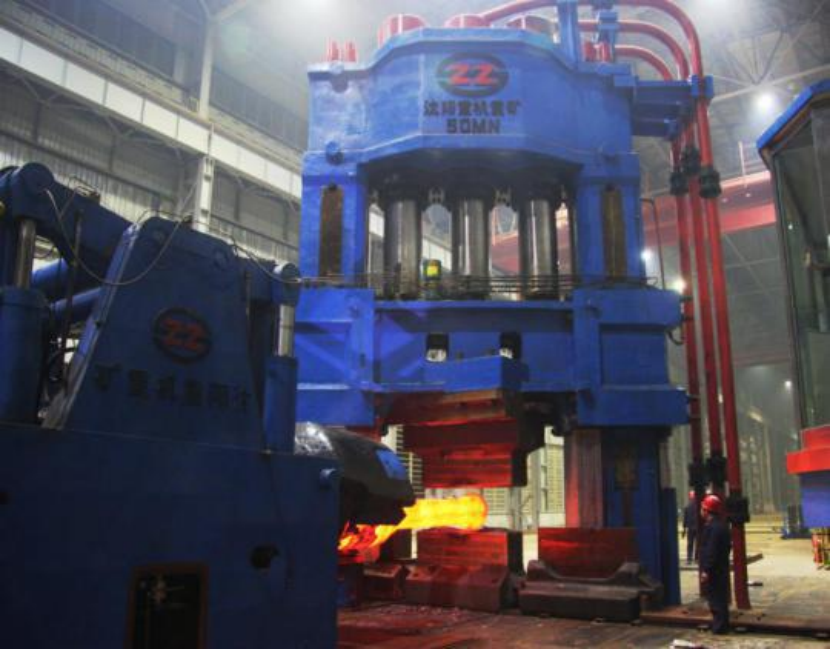

Parts of forged steel rolls production equipments photos

Movable tank truck type LF-VD

Forging heat furnace

45MN hydraulic hammer press

Quenching machine

Liquid nitrogen cryogenic tank

Inspect the metallographic structure

Ultrasonic inspection