- Juncheng

- China

- 100 days to 150 days

- 80000 tons/year

Grade properties: The eutectic carbide (M7C3 type) in the structure accounts for 20%-30% and is in the form of intermittent network, so the roll has high wear resistance. The matrix structure is composed of tempered martensite and sorbite, with fine and dispersed secondary carbides (M23C6 type) distributed on it, thus increasing the wear resistance of the roll. The Cr203-rich film covering the surface of the roll has high-temperature oxidation strength and plastic deformation resistance, making this type of roll particularly suitable for hot rolling of steel.

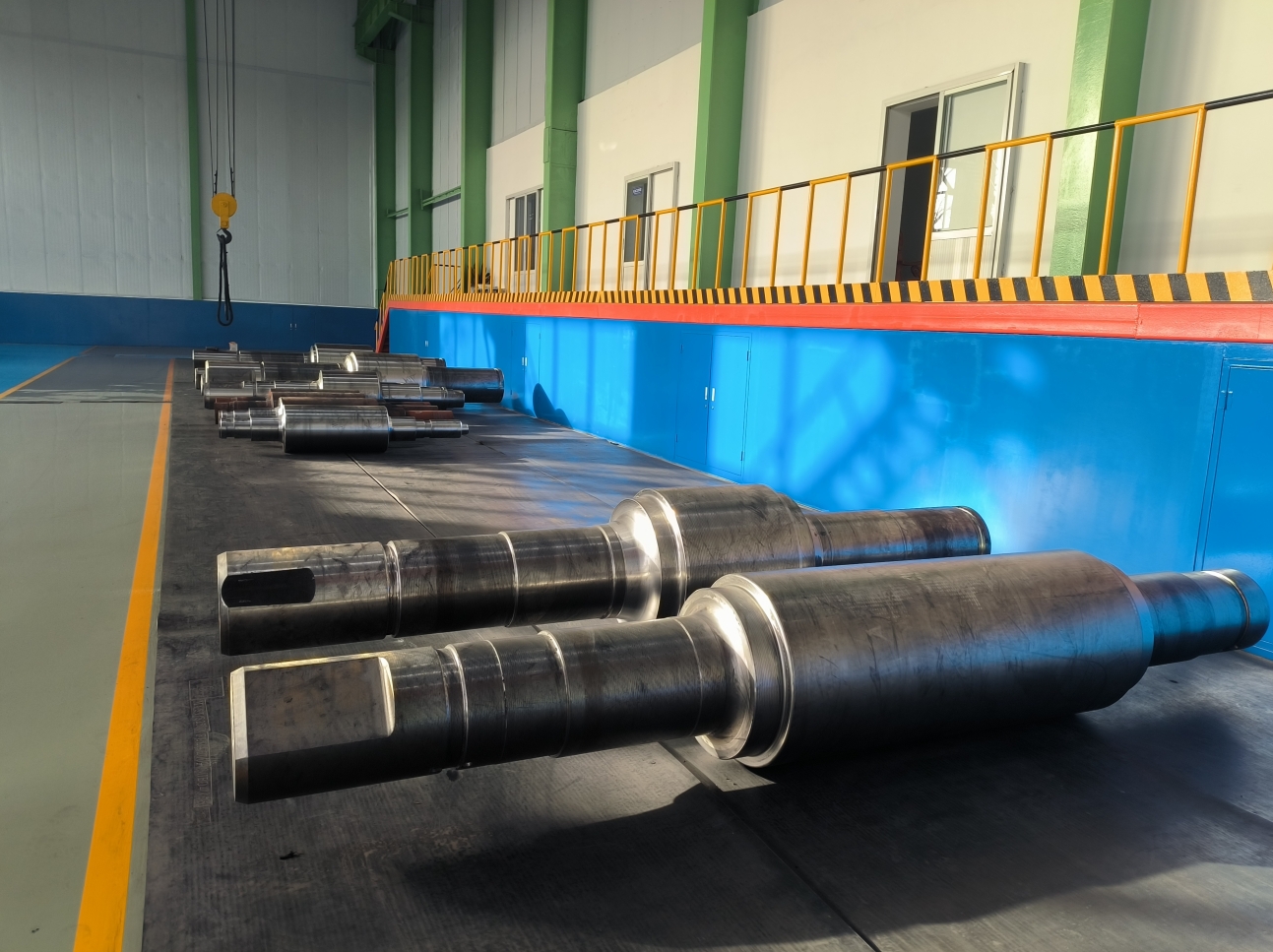

Centrifugal and static cast high Chrome(Cr) cast iron roll

Chemical:

Grade | HSD | C | Si | Mn | Ni | Cr | Mo |

High Chrome | 40/60 | 1.3/2.3 | 0.3/0.6 | 0.6/1.2 | >=0.2 | 0.8/1.6 | 0.2/0.6 |

Mechanical

Hardness | Centrifugal | Static |

|

Shell | HSD40-60 | HSD40-60 | |

Core | HSD35-50 | HSD40-55 | |

Core TRS | >=450 Mpa | >=490 Mpa | Mag X 100 |

Application:

Hot rolling steel sheet and coil finish work stands rolls.