- Jun Cheng

- China

- 100 days to 150days

- 80000tons/year

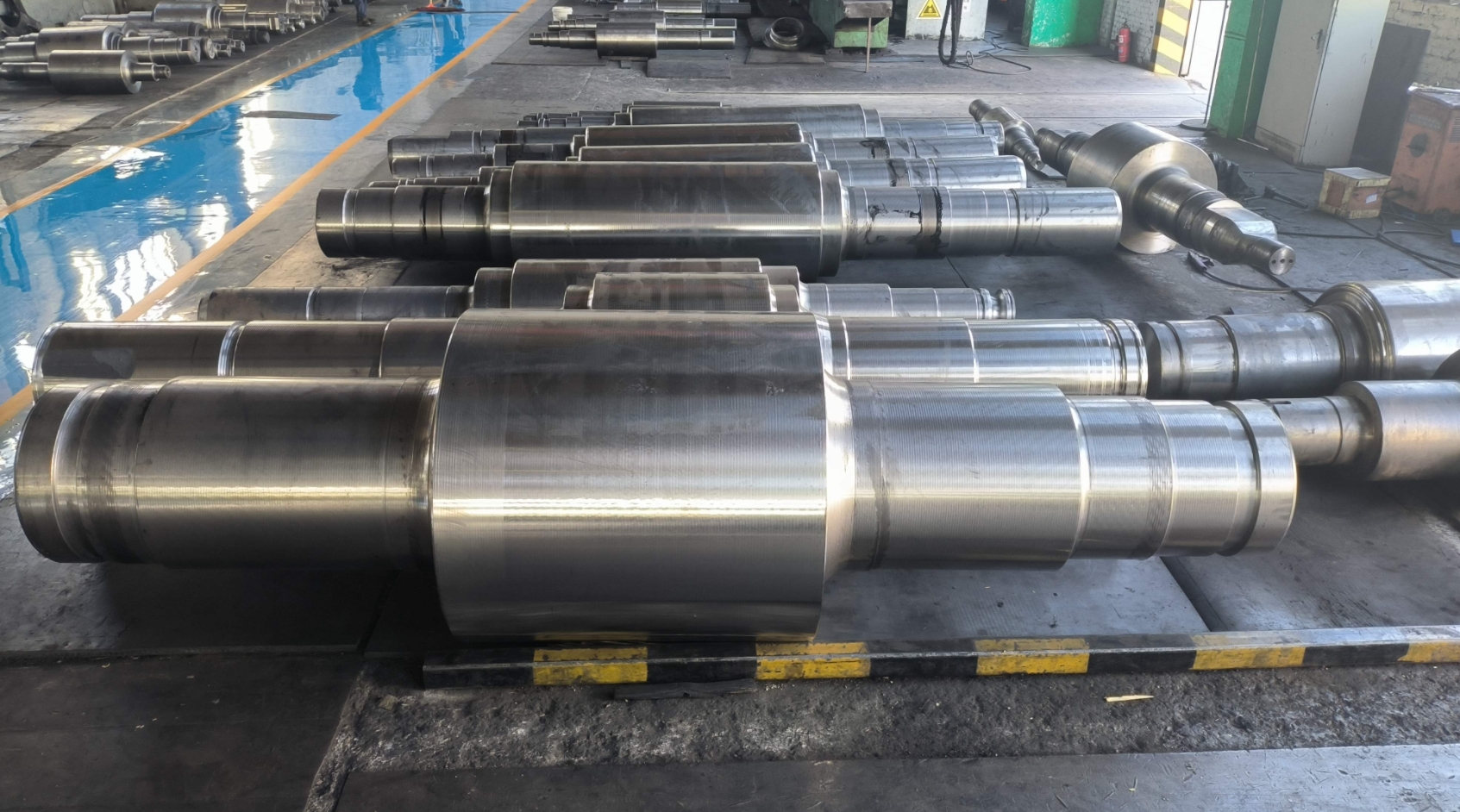

The outer layer of the improved high-chromium steel centrifugal composite roller has higher chromium alloy content, and niobium, vanadium, tungsten and other strong carbide elements are added to carry out multi-element alloying; after the roller is subjected to spray quenching and twice tempering heat treatment,The outer layer is composed of tempered martensite and compound granular carbides(M7C3+ MC + M2C + M6C), which can improve the wear resistance of the roll significantly. The core is made of high strength ductile iron, which has excellent comprehensive performance.

Centrifugal cast High-Chromium steel (improved)

Chemical

C | Si | Mn | Ni | Cr | Mo | V+Nb+W |

1.0/1.5 | 0.4/0.8 | 0.5/1.0 | 0.6/1.5 | 8/15 | 1.5/2.0 | 0.2/2.0 |

Mechanical

Hardness | Centrifugal |

|

Shell | HSD70-85 | |

Core | HSD35-45 | |

Core TRS | >=450 Mpa | Mag X 100 |

Application

Hot rolling strip rough stand and vertical roll, universal mill rolls