- Juncheng

- China

- 30 days to 60 days

- 3000pcs/month

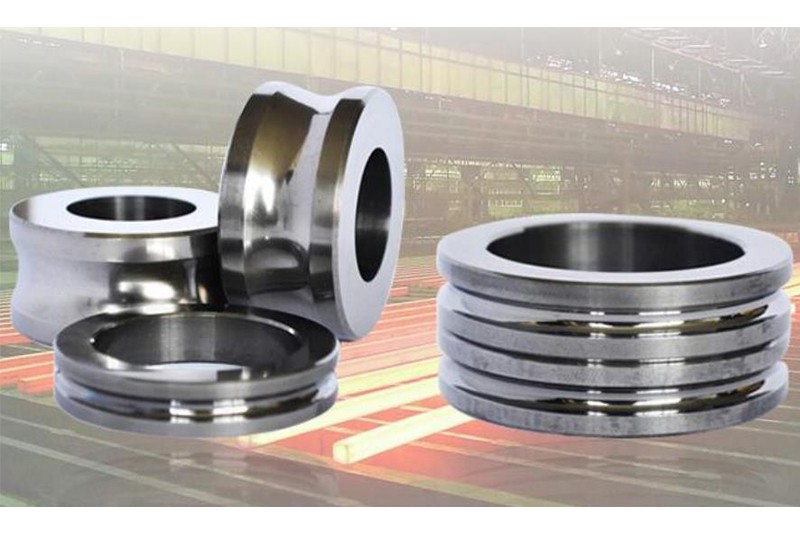

TiC guide roll advantages:

- HIP treatment and therefore show no micro porosities.

- High wear resistance and toughness

- Lighter than tungsten carbide by 55%

- Machinable and heat-treatable

- Vould be reused after re-turning and re-grinding

- Temperature resistance as high as 800°C.

Properties of TiC guide roller

TiC guide roll features:

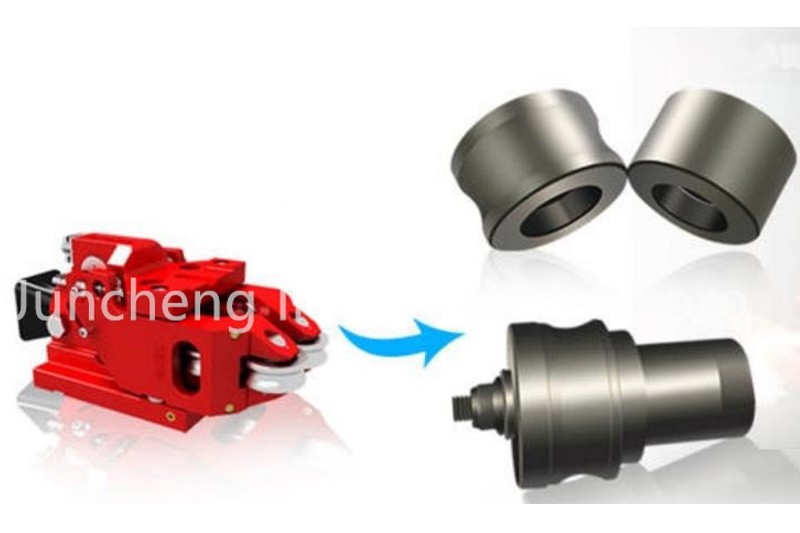

1. Steel-bonded hard alloy high-line precision rolling guide roller guide roller, with high hardness (hardness after quenching and tempering can reach HRC60 ~ 72), high wear resistance, high impact resistance and good hardening Permeability; a large amount of refractory metal carbide (titanium carbide) is dispersed in the product, which has a high hardness, which greatly improves the wear resistance of the product. At the same time, it also has the advantages of heat treatment and weldability, has a lower heat treatment deformation rate, and greatly improves the physical and mechanical properties of the threaded sleeve.

2. Steel-bonded cemented carbide high-wire finishing rolling guide rollers have extremely low friction coefficient and self-lubricating performance, as well as good oxidation and corrosion resistance.

3. Steel-bonded cemented carbide high-line precision rolling guide rollers and guide wheels have high elastic modulus and rigidity and excellent damping characteristics, which can eliminate vibration caused by itself and even the machine. It is a good rigid anti-vibration tool And parts.

4. Steel-bonded cemented carbide high-line precision rolling guide rollers and guide wheels have good machinability, and can be processed by ordinary machining equipment and tools such as turning, milling, planing, drilling, and grinding.

5. Steel-bonded cemented carbide high-wire finishing rolling guide rollers and guide wheels, with forgeability. It can change its shape and size through forging, improve the internal structure of the material, and thus improve its performance.

6. Steel-bonded cemented carbide high-line precision rolling guide roller guide wheels have better impact toughness and excellent cost performance. Compared with tungsten-cobalt cemented carbide, the density of steel-bonded gold is about 6.5g / cm3 There are good cost-effective advantages.

Our TiC guide roll grade is JCT-3, performance as follow :

| Density (g/cm2) | Compressive Strength (N/mm2) | Transverse Rupture Strength (N/mm2) | Modules of Elasticity (N/mm2) |

| 6.5 | 3800 | 2300 | 295000 |

| Impact Strength (kg-m/cm2) | Coefficient of Thermal Expansion (10-6/0C) | Annealing Hardness (HRC) | Service hardness (HRC) |

| 80 | 9 | 51 | 66-69 |

Guide roller guide roller instructions:

1. The service life of the guide roller and guide wheel determines 2 aspects:

I is the service life of the material of the guide roller and guide wheel, and

II is the service life of the bearing. Because the cooperation between the bearing and the guide roller is an interference fit, once it is assembled, it cannot be removed, so it is important to match the service life of the guide roller and the bearing.

At present, the bearings used in China are of low and medium quality. There are very few high-quality bearings. The bearings do not match the steel-bonded carbide guide rollers. The service life of the steel-bonded carbide guide wheels is much longer than the bearing life. This is also the main reason for the lack of promotion of steel-bonded carbide guide rollers. However, high-quality bearings are used abroad, and their service life can be well matched with steel-bonded hard alloy guide wheels, so they can be used well. Method for improving the service life of rolling mill guide rollers: In order to improve the wear resistance and crack resistance of rolling mill guide rollers, a new powder metallurgy production technology of steel-bonded hard alloy material guide roller guide wheels and conventional high chromium cast steel Compared with guide rollers and guide wheels, its service life is greatly improved. The service life of high chromium cast steel guide rollers is generally 8 hours. After that, severe wear grooves and fatigue cracks will appear. Deep grooves generated by wear will cause steel sticking and stuck steel, which will seriously affect the surface quality of the steel, thus Scrap invalid. Steel-bonded carbide guide rollers have significant resistance to abrasive wear and thermal fatigue, and their average service life is 800 hours. In addition, after repairing the guide roller guide wheels, their average life can be increased More, the effect is very significant.

Through comprehensive evaluation of steel-rolled carbide guide rollers and guide wheels, it can be known that the application of steel-bonded carbide guide rollers and guide rollers on rolling mills can significantly increase the service life of rolling mill guide rollers, thereby reducing the number of guides. Roller loading and unloading costs, reducing labor intensity of frequent replacement and waste of rolling work time caused by disassembling and handling of guide rollers, can increase the amount of steel rolling, save a lot of high-quality steel, and reduce safety caused by damage to guide rollers accident.