- Juncheng

- China

- 30 days to 60 days

- 200sets/month

Composite roll are rollers which fix tungsten carbie rings on steel roll shaft by a certain way. The fixing ways include : mechanical combination, casting way(CIC) , metallurgy way and bond way.

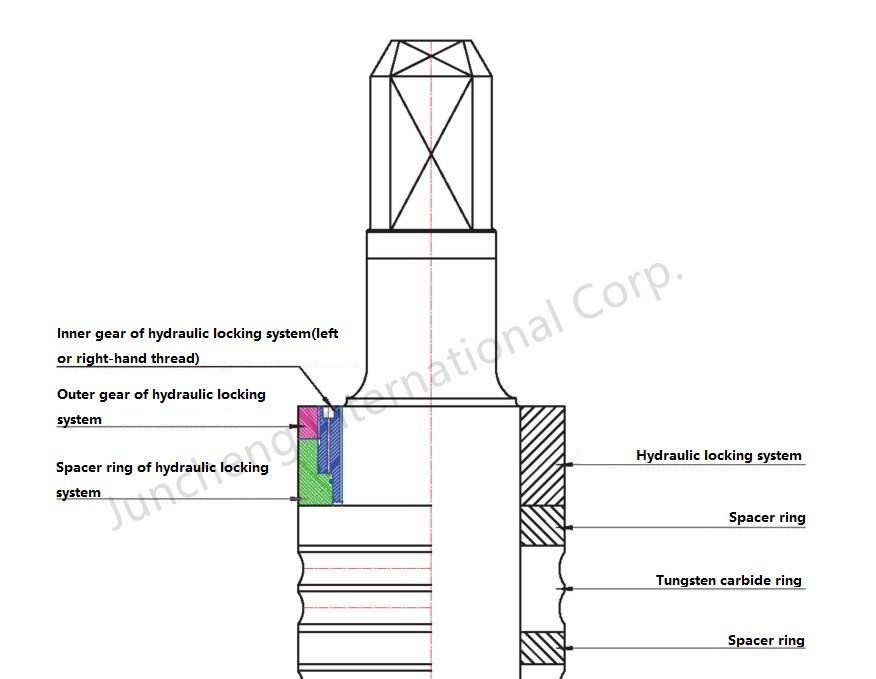

Now the mechanical combination way is mainstream, the representative companies are Juncheng Corp. China, Teatugec Korea, SinterMet America and Mitsubishi Japan. Juncheng composite rolls are fixed by hydraulic locking system.

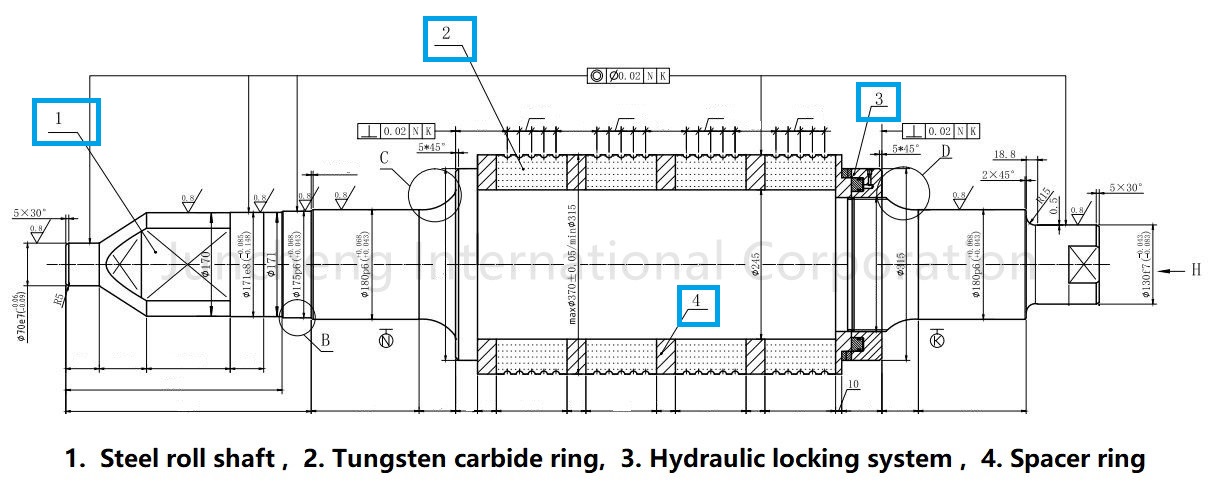

1. Composite roll structure

Components include : steel roll shaft ; tungsten carbide ring; hydraulic locking system; spacer ring

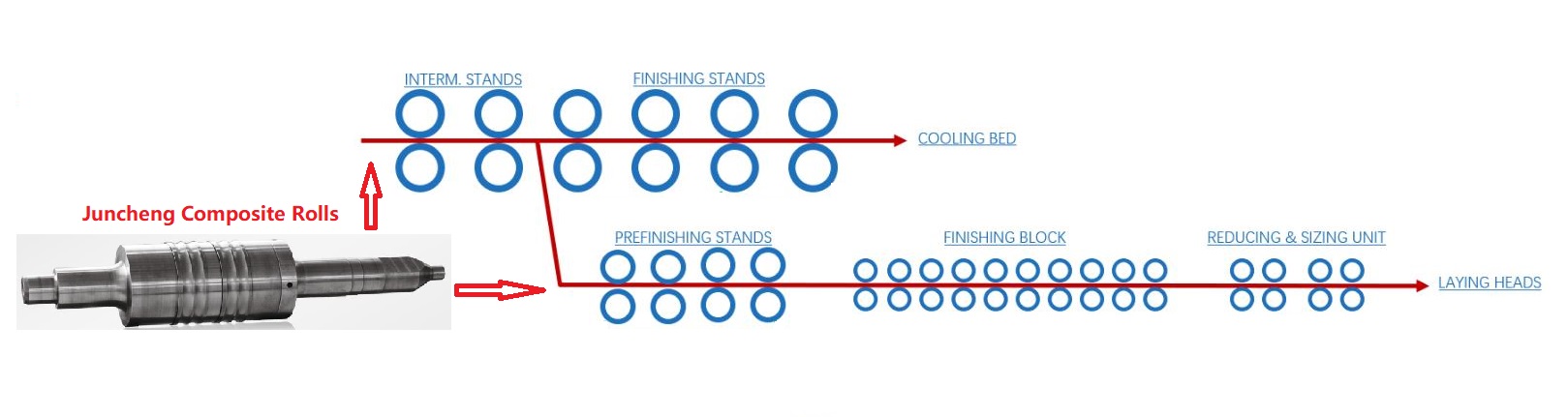

2. Range of application

Suitable for intermediate stands, pre-finishing stands, finishing stands, finishing block, reducing & sizsing stands.

Milling rod, rebar ,wire, coil, angle steel of normal carbon steel, stainless steel, alloy steel for high speed rolling and normal different rolling speed.

3. Advantage of Juncheng composite roll

* Increased single groove rolling capacity 10 to 20 times compared with nodular cast iron rolls. Because the TC rings hardness are much higher , they are more wearable, its usage reduces times of changing grooves and rolls obviously, then the mill roll efficiency improoved much.

* Reduce the rolls processing and repairing costs because TC rolls are more durable.

* Increase yield and rate of finished products.

Usage of TC rolls can increase the size accuracy of products, then reduce scrap rate. Reduce the groove changing times, it means the entry and exist guide times reduced also, this decrease pilling-up of steel ( steel heaping) and scrap finally.

* Reduce labor intensity by decreasing grooves changing times.

* Enhance surface quality of rolled metal. The rolled round metal have very high surface smoothness, minus deviation controled precisely.

4. Recommended TC ring grades

Grade | Co+Ni+Cr% | WC% | Density g/cm3 |

Hardness HRA

| T.R.S. N/mm2 | Compressive strength N/mm2 |

JC20 | 20 | 80 | 13.6 | 82 | 2580 | 3100 |

JC20X | 20 | 80 | 13.4 | 82.5 | 2650 | 3000 |

JC25 | 25 | 75 | 13.1 | 80 | 2500 | 2900 |

JC27 | 27 | 73 | 12.9 | 78.5 | 2400 | 2700 |

JC28 | 28 | 72 | 12.8 | 78.5 | 2300 | 2600 |

JC30 | 30 | 70 | 12.6 | 77.5 | 2300 | 2600 |

JC30X | 30 | 70 | 12.7 | 79.5 | 2550 | 2800 |

5. Pre-sales information collect of composite roll

For the cast iron and steel rolls changed into composite rolls, please supply follow datas:

1, the drawing of iron rolls,

2, the detailed drawing of the groove on iron roll

3, rolling materials, rolling speed

4, max and min working diameter of iron rolls

We need above information at least to design the composite rolls for you.

The composite rolls we have made and sold are more than 500sets, so we have good experiences to meet your requiments.