hss roll

-

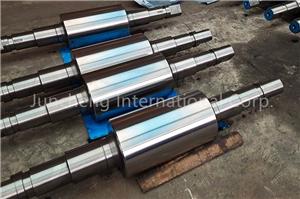

HSS Roll

Compared with traditional ductile iron roll and high Ni-Cr roll, high-speed steel roll has higher wear resistance and higher single-pass over-steel volume, saving the roll change time, improving mill operating rate, reducing roll consumption and reducing Production costs, improve the overall efficiency of the factory. General one groove carrying capacity is 3 to 5 times than nickel-chromium roll. The following table is the use of high speed steel roller and bainitic ductile iron bar in the bar machine on the effectiveness of the comparison.

Email Details -

High Speed Steel Roll ( HSS roll)

Grade properties: The outer layer is high-carbon alloy steel containing Cr, Mo, W, V, and Nb. The complex carbide structure is embedded in the tempered martensite structure. The carbon content and comprehensive heat treatment are controlled to optimize wear resistance and resistance to corrosion. Thermal fatigue. The oxide film structure on the surface maintains a low residual stress value.

Email Details -

Composite And HSS Roll CNC Grinding Machine

This machine is mainly used for rough grinding, semi-precision grinding, fine grinding and non-sparking of the outer circle and R-groove of tungsen carbide composite roll or high-speed steel roll for bar or coil production. Grinding and other grinding processes, at the same time, after the installation of the transition disk, the automatic centering and tightening mandrel can be used to process a single roll ring, which expands the use of the machine tool.

CNC grinding machine composite roll grinding machine HSS roll grinding machine mill roll grinding machineEmail Details